In today's fast-paced food and beverage industry, businesses face multiple challenges: how to ensure product freshness and safety, how to optimize transportation and storage costs, and how to respond to the growing demand for eco-friendly solutions. Traditional packaging forms, such as glass bottles and plastic drums, often have limitations in convenience and cost-effectiveness. Glass is fragile and heavy, with high recycling costs, while plastic, though lightweight, may pose safety and environmental concerns.

It is in this context that Jam & Juice Bag-In-Box (BIB) Packaging has emerged as an innovative solution. It cleverly combines a flexible, high-barrier inner bag with a sturdy, foldable outer box, providing excellent protection for liquid foods like jams and juices. This packaging not only significantly extends product shelf life but also effectively reduces logistics costs and environmental footprint.

| Feature | Traditional Packaging (e.g., Glass Bottles/Plastic Drums) | Jam & Juice Bag-In-Box (BIB) |

| Weight | Heavy, especially glass bottles | Lightweight, significantly reduces transport weight |

| Space Utilization | Round or square containers with significant empty space | Foldable, effectively saves storage and transport space |

| Damage Rate in Transit | Glass is fragile, high breakage rate | Extremely low, strong impact resistance |

| Shelf Life | Susceptible to light and air | Excellent barrier properties, extends shelf life |

| Product Residue | A lot of product can be left on container walls | Easy to empty completely, reduces waste |

| Eco-friendliness | High glass recycling cost, plastic is difficult to degrade | Eco-friendly materials, recyclable, easy to compress and dispose of |

| Dispensing Convenience | Usually requires pouring or using a pump | Compatible with dispensing systems for precise and easy serving |

Jam & Juice Bag-In-Box (BIB) Packaging is a modern packaging solution specifically designed for the transportation and storage of large volumes of liquid food. Its core concept is to provide a system that combines protection, convenience, and efficiency. It consists of two main parts: a flexible inner bag and a sturdy outer box.

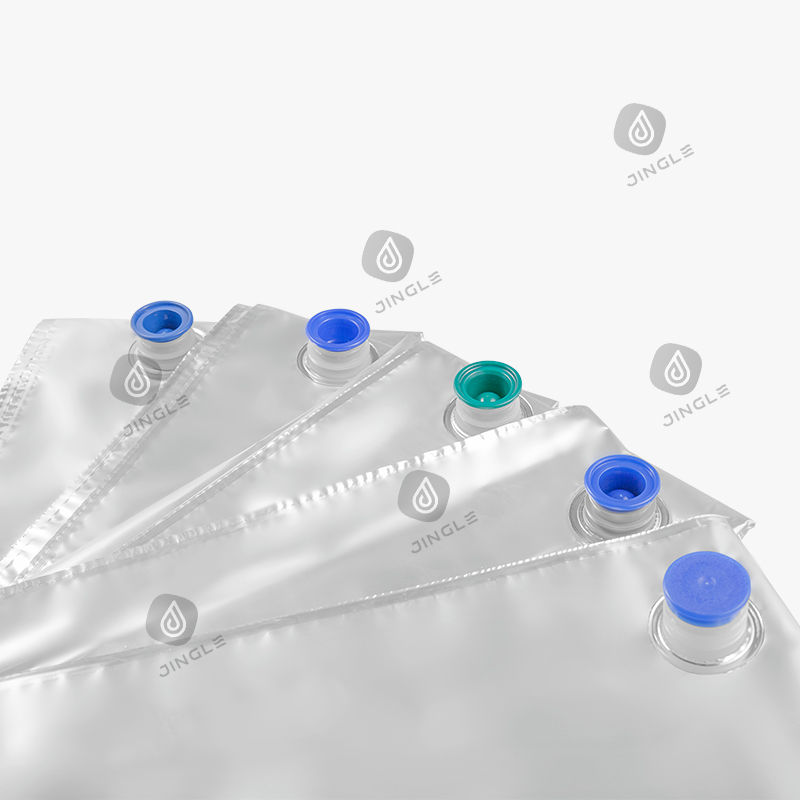

This is the part that is in direct contact with the jam and juice, typically made from multi-layer composite materials. These materials have extremely high barrier properties, effectively preventing the penetration of oxygen, light, and moisture, thereby maximizing the product's shelf life and maintaining its freshness. The bag's port is usually equipped with a specific valve or spout, making it easy for filling and subsequent liquid dispensing. Many advanced inner bags utilize aseptic bag-in-box technology, where filling is done in a sterile environment to further ensure the safety and stability of the product.

The outer box is typically made from durable corrugated cardboard. Its primary role is to provide structural support and physical protection for the inner bag, preventing it from being squeezed or punctured during transport and handling. Additionally, the outer box serves as a platform for displaying brand information, product instructions, and logistical details. With the help of the outer box, multiple BIB packages can be easily stacked, significantly improving warehousing and transportation efficiency.

The design of BIB packaging was originally intended to replace traditional barrels or bottles for the **bulk** distribution of liquid food. Its compact, stackable nature makes it especially popular in the BIB packaging for food service industry, such as restaurants, hotels, and cafes, for dispensing concentrated juices, syrups, or edible oils. It not only reduces the hassle of repeatedly purchasing small packages but also significantly lowers the generation of packaging waste.

| Feature | Jam & Juice BIB Packaging | Traditional Plastic Drums |

| Space Utilization | High space utilization as the bag collapses after liquid is dispensed | Retains a fixed shape, occupies a large amount of space |

| Residue Rate | Bag design allows for almost complete emptying, minimal product waste | Significant liquid residue can be left at the bottom and on inner walls |

| Shelf Life | Excellent barrier properties, maintains freshness after opening | Air enters with each use, susceptible to oxidation and spoilage |

| Stackability | Regular square shape, allows for efficient stacking | Irregular shape, stacking is unstable |

| Transport Efficiency | Can be compressed, empty boxes have small volume, low transport costs | Fixed shape, high cost for returning empty drums |

Jam & Juice Bag-In-Box (BIB) Packaging stands out among various packaging solutions due to its three core advantages in preservation, cost-efficiency, and environmental friendliness. These benefits not only solve the pain points of traditional packaging but also bring tangible value to businesses and consumers.

The preservation capability of BIB packaging is one of its biggest selling points. The secret lies in the aseptic bag-in-box technology used for the inner bag. This multi-layer composite material bag has very high barrier properties that effectively block light and oxygen. As jam or juice is dispensed from the BIB package, the inner bag collapses, creating a vacuum environment. This means the product does not come into contact with air even after opening, thus preventing oxidation and microbial contamination, and significantly extending its shelf life.

| Feature | BIB Packaging (After Opening) | Traditional Bottled Packaging (After Opening) |

| Air Exposure | Almost zero, as the bag collapses | Air enters with each use |

| Oxidation Risk | Extremely low | High risk of oxidation due to continuous air exposure |

| Shelf Life Extension | Significantly extended, maintains flavor | Spoils quickly, must be used promptly |

| Freshness | Maintains original flavor and nutrition | Flavor degrades over time |

For the BIB packaging for food service industry, BIB packaging is a highly cost-effective choice. First, its lightweight and foldable nature significantly reduces transportation costs. An empty BIB package takes up almost no space, and full ones can be stacked efficiently, maximizing the use of truck and warehouse space. Second, its matching packaging system dispensing systems simplify operations and allow for precise measurement, reducing waste caused by human error. Finally, its excellent emptying performance ensures high product utilization, with almost no residue, which is crucial for high-volume commercial environments.

In a world where sustainable development is increasingly important, the environmental advantages of BIB packaging cannot be overlooked. Its lightweight design means lower energy consumption and fewer carbon emissions during transportation. More importantly, most of its materials are recyclable. The corrugated cardboard outer box can be recycled and reused, and the inner bag can also be disposed of correctly. Compared to bulky glass bottles or large plastic drums, BIB packaging is easier to compress and handle after disposal, effectively reducing landfill burden and aligning with modern society's pursuit of green and eco-friendly packaging.

The versatility of Jam & Juice Bag-In-Box (BIB) Packaging allows it to be widely used across various industries, especially in scenarios requiring large-volume liquid food dispensing. At the same time, its efficient operation relies on advanced technical support.

The true value of BIB packaging lies in its seamless integration with dispensing systems for liquid food. These systems can be customized to meet the needs of different venues, such as:

In restaurants, cafes, and bars, BIB packages can be connected to automatic juice machines or concentrated syrup dispensers. This system can precisely control the output volume, ensuring consistent taste and sweetness for every drink while simplifying the workflow for staff.

At hotel buffets or banquets, BIB packaging provides a hygienic and efficient way to dispense juices and jams. Compared to traditional juice pitchers, it reduces spills and waste, and ensures a continuous supply of the product.

| Feature | Manual Dispensing Systems (with Valve) | Automatic Dispensing Systems |

| Operation | Manually open valve, pour or squeeze | Automatic dispensing via button or sensor |

| Dispensing Accuracy | Dependent on operator experience, can be imprecise | Precise and quantifiable, can be programmed |

| Application Scenario | Homes, small-scale food outlets | Large and medium-sized restaurants, buffets, commercial kitchens |

| Cost | Low initial investment | Higher initial investment, but high long-term returns |

The safety of BIB packaging is centered on its food grade BIB liner. This inner bag is made of multiple layers of special materials designed to ensure the contents are protected from external contamination throughout their lifecycle.

Typically made of food-grade materials like polyethylene (PE), which are chemically inert and will not react with jam or juice, ensuring the food's flavor and quality are unaffected.

Located in the middle, usually made of EVOH (Ethylene-Vinyl Alcohol Copolymer) or aluminum foil. These materials are crucial for preventing oxygen, water vapor, and light from entering, which is especially vital for easily oxidized components like Vitamin C.

Provides structural strength and abrasion resistance, protecting the inner layers from damage during handling.

By using these high-tech composite materials, BIB packaging not only extends product shelf life but also maintains the natural flavor, color, and nutritional components of jams and juices without the need for excessive preservatives, providing consumers with a healthier and safer product.

Jam & Juice Bag-In-Box (BIB) Packaging is more than just a form of packaging; it represents a significant innovation in the food and beverage industry regarding efficiency, sustainability, and product safety. By combining aseptic bag-in-box technology with a sturdy outer box, BIB packaging provides a comprehensive solution for liquid products like jams and juices.

From manufacturers to end-users, the advantages of BIB packaging span the entire supply chain. Its lightweight and stackable design significantly reduce transportation and storage costs, setting a new industry standard for bulk beverage containers. For the food service industry (BIB packaging for food service), it greatly simplifies the dispensing process, reduces waste, and ensures consistent product quality.

Furthermore, BIB packaging addresses the current market demand for both eco-friendliness and health. It uses recyclable materials, reduces its environmental footprint, and, through its excellent barrier properties, extends product shelf life without relying on a large amount of preservatives.

| Core Advantages | Brief Description |

| Preservation & Safety | Excellent barrier properties and aseptic filling technology effectively extend shelf life and maintain product flavor and nutrition. |

| Economy & Efficiency | Lightweight, foldable design significantly reduces transport, storage, and dispensing costs, minimizing material waste. |

| Eco-friendliness & Sustainability | Uses recyclable materials, reduces carbon footprint, is easy to compress and dispose of, aligning with eco-friendly trends. |

In summary, Jam & Juice Bag-In-Box (BIB) Packaging, with its unique structure and technology, is reshaping the landscape of liquid food packaging. For businesses that prioritize efficiency, safety, and sustainability, it is undoubtedly an innovative option worth deep consideration and adoption.

Suzhou Jingle Packaging Technology Co., Ltd. specializes in the development and production of high-quality liquid flexible packaging products. Our **Jam & Juice Bag-In-Box (BIB) Packaging** offers multiple advantages. Our advanced BIB production line can produce a wide variety of products according to customer requirements to meet diverse market demands. With over 15 years of industry experience and deep technical knowledge, our team provides customized, comprehensive solutions that ensure products have excellent preservation, cost-effective transportation, and sustainability, helping you stand out in a competitive market.

At **Suzhou Jingle Packaging Technology Co., Ltd.**, product quality and safety are our top priorities. The inner bags of our BIB packaging are made from high-barrier, food-grade composite materials to ensure the contents are protected from external light, oxygen, and moisture. We are committed to continuous research and development, and our products strictly adhere to quality standards. They are also designed to work perfectly with corresponding filling equipment, providing safe and reliable packaging solutions for the food, beverage, and non-food sectors. We understand the importance of food packaging, and our products are designed to effectively protect your jams and juices, preserving their freshness and nutritional content.

In addition to our core BIB packaging products, we offer a comprehensive range of solutions for our customers. As a company located in Suzhou, we are more than just a packaging supplier; we also provide supporting filling equipment and corresponding after-sales services. Our team has a deep understanding of various market applications and can work closely with customers to actively explore new market opportunities. Whether you need customized packaging design or a complete filling and dispensing solution, **Suzhou Jingle Packaging Technology Co., Ltd.** can provide professional support to meet your specific needs.