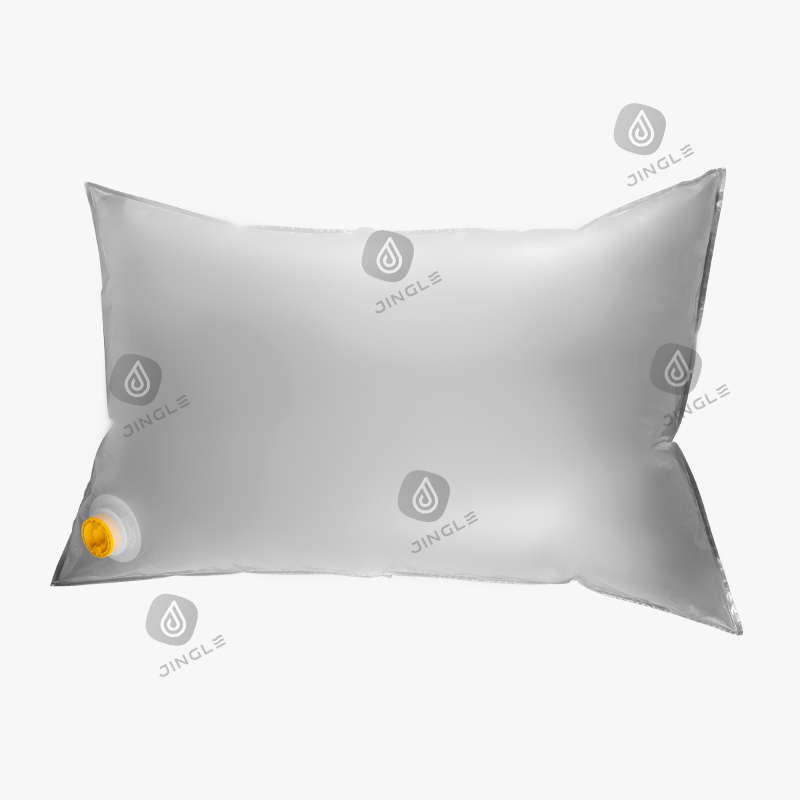

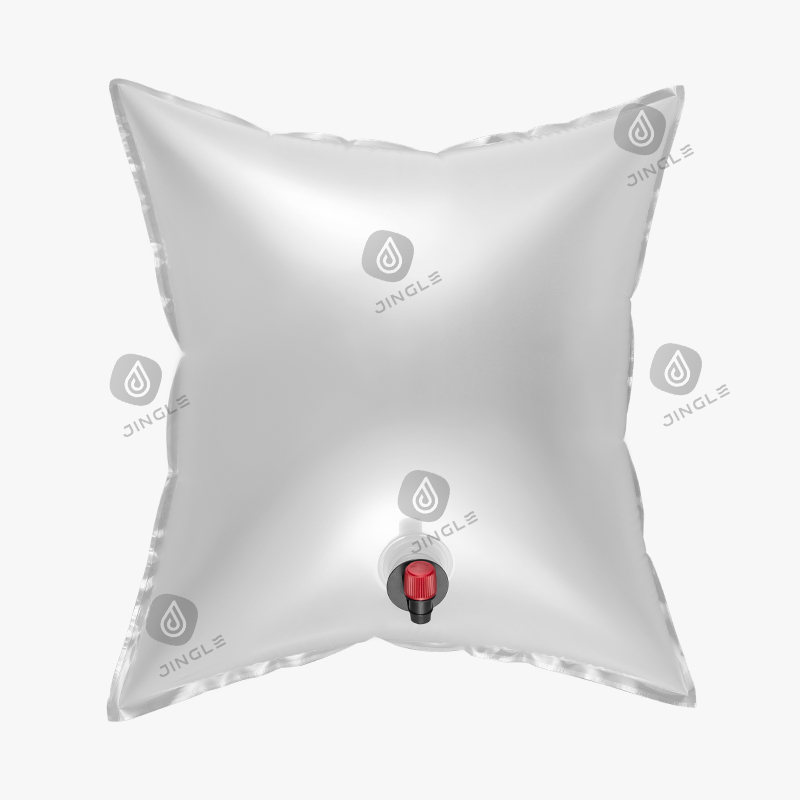

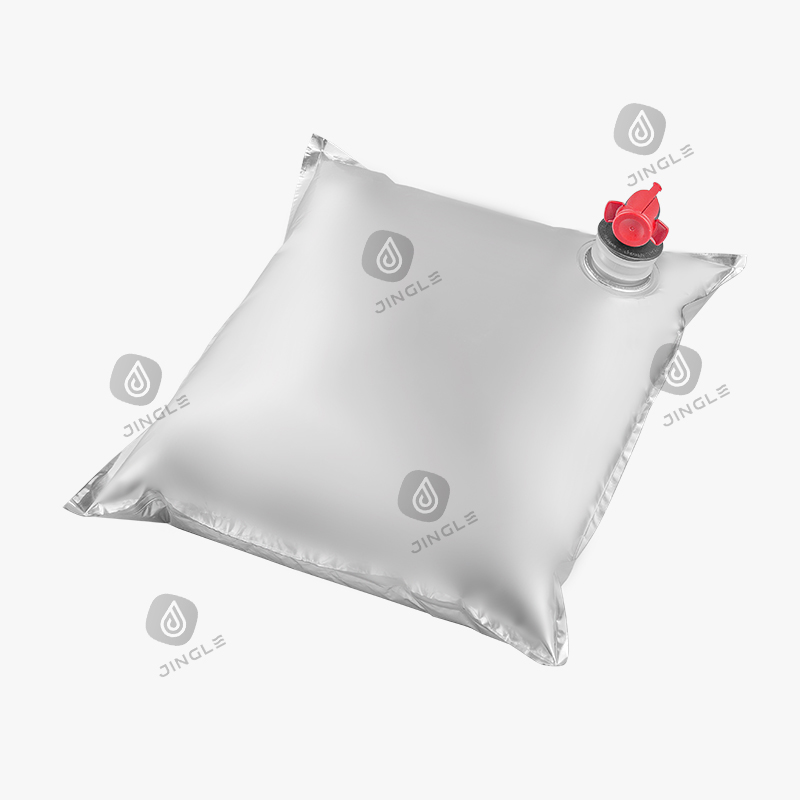

Car Supplies Bag-In-Box (BIB) Packaging - Efficient Liquid Storage and Distribution Solution

Product Features

- Space-efficient structure: Collapsible design minimizes storage and transportation costs compared to rigid containers.

- Controlled dispensing system: Integrated spout ensures consistent flow and reduces risk of contamination.

- Material compatibility: Multi-layer film construction designed to protect automotive fluids such as windshield washer liquid, coolant, and lubricants.

Product Description

The Car Supplies Bag-In-Box (BIB) Packaging is engineered for the storage, transport, and dispensing of liquid automotive consumables. The packaging system combines an inner flexible bag with an outer corrugated carton, offering protection against external pressure and light exposure. Its structure enables streamlined filling, transportation, and dispensing processes.

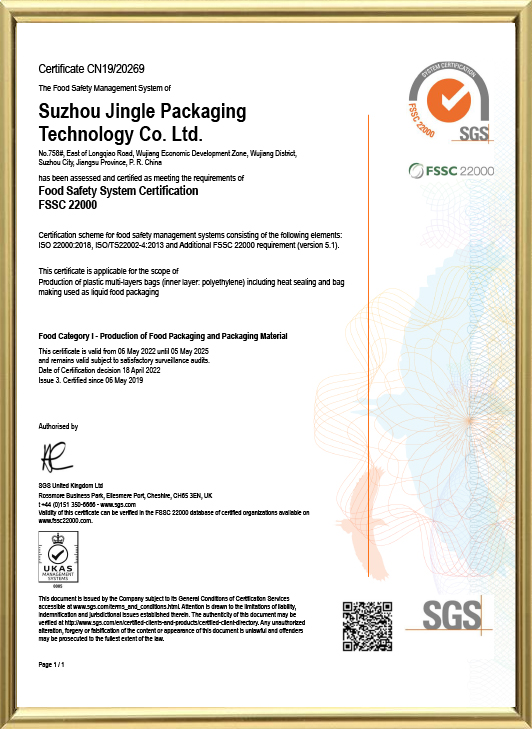

This packaging format complies with international packaging safety guidelines for automotive chemicals and consumables. Its barrier films and sealing technology enhance product shelf life while minimizing oxygen and moisture penetration.

Technical Specifications

| Specification | Details |

| Capacity range | 2L – 20L |

| Film material | Multi-layer PE/PA or PE/EVOH |

| Outer carton | Reinforced corrugated board |

| Spout type | Tamper-evident dispensing fitments |

| Sealing method | Heat-sealed for leak prevention |

| Operating temperature | -10°C to 60°C |

Application Fields

This product is applicable in the following industrial scenarios:

- Distribution of windshield washer fluids in automotive workshops and retail channels

- Coolant and antifreeze storage for service stations

- Lubricant oil packaging for fleet maintenance facilities

- Bulk automotive chemical logistics requiring reduced secondary packaging waste

FAQ

1. What automotive fluids can be packaged in a Bag-In-Box system?

The Bag-In-Box packaging is compatible with a wide range of non-corrosive automotive fluids, including windshield washer fluid, antifreeze, coolant, and certain lubricant oils. Compatibility with specific formulations should be confirmed through laboratory testing.

2. How does Bag-In-Box packaging reduce costs in automotive fluid distribution?

The collapsible inner bag and lightweight outer carton reduce freight weight and storage volume. This leads to lower logistics costs compared to rigid plastic containers while also simplifying recycling and waste management.

3. What is the shelf life of automotive fluids in BIB packaging?

Shelf life depends on fluid type and film composition. Typically, multi-layer barrier films extend protection by limiting oxygen and UV exposure, maintaining fluid integrity for 12 to 24 months under proper storage conditions.