For high-volume producers of liquid concentrates, the integrity of Tea & Coffee Liquid Bag-In-Box (BIB) Packaging dictates product quality and market reach. Achieving an Extended shelf life Bag-In-Box for beverages of six months or more at ambient temperature relies on two integrated engineering principles: robust oxygen barrier film and validated aseptic processing. Technical buyers must specify the precise Oxygen Transmittance Rate (OTR) of the internal liner to prevent flavor degradation and chemical oxidation.

Oxygen ingress is the primary failure mode for liquid coffee and tea concentrates, causing staling, oxidation of sensitive flavor compounds, and discoloration. Controlling this requires setting stringent OTR requirements for liquid food packaging.

For liquid tea and coffee requiring an ambient shelf life of six months or more, a standard low-barrier film is inadequate. The packaging system requires a thin-film OTR well below 1.0 cc/100 in²/24 hrs, usually targeting a value closer to 0.05 cc/100 in²/24 hrs to ensure maximum protection. This precision is essential for achieving the necessary preservation and quality retention for Tea & Coffee Liquid Bag-In-Box (BIB) Packaging.

| Film Type | Typical OTR Range (cc/100 in²/24 hrs) | Suitability for Coffee/Tea Concentrate |

|---|---|---|

| Standard LDPE Film | 100 - 150 | Poor (Only for immediate use or non-sensitive liquids). |

| Metallized PET (METPET) | 0.1 - 0.5 | Good (Sufficient for moderate shelf life, dependent on pinhole integrity). |

| EVOH/Foil Laminate | < 0.05 (Ideal for **High oxygen barrier film for coffee BIB**) | Excellent (Required for 6+ month ambient preservation). |

Achieving the low OTR thresholds necessary for High oxygen barrier film for coffee BIB requires sophisticated material science, moving beyond simple mono-layer polymers.

Both EVOH (Ethylene Vinyl Alcohol) and aluminum foil laminates are utilized for barrier layers, but they possess different technical merits. Foil offers near-zero OTR and moisture barrier, essential for the longest shelf lives, but is susceptible to flex-cracking. EVOH offers transparent high-barrier properties ideal for products requiring heating or specific processing steps, though its OTR is moisture-dependent. The choice depends on the specific product's requirements for barrier integrity and visual inspection.

The best barrier film is useless if the filling process introduces contaminants. Aseptic filling technology for liquid tea packaging provides the second pillar of preservation.

The combination of ultra-low OTR **Tea & Coffee Liquid Bag-In-Box (BIB) Packaging** (preventing chemical degradation) and validated aseptic processing (preventing biological degradation) is the only reliable method for achieving and maintaining 6-12 month ambient shelf lives for oxygen-sensitive liquid concentrates.

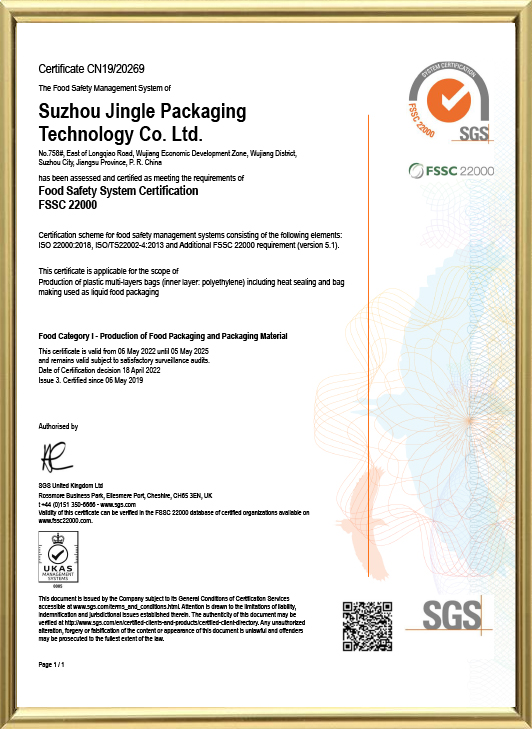

Suzhou Jingle Packaging Technology Co., Ltd., located in the Wujiang Economic Development Zone near Shanghai, is dedicated to developing and producing liquid flexible packaging. Our advanced BIB production line allows us to engineer custom Multi-layer films for BIB packaging tailored to stringent demands, such as the low OTR requirements for liquid food packaging needed for coffee and tea concentrates. Our team members, with over 15 years of industry experience, possess strong technical knowledge and familiarity with various market applications, specializing in liquid flexible packaging for food, beverage, and non-food fields. We provide quality products, comprehensive solutions, supporting filling equipment, and after-sales services, actively exploring new market opportunities with our local and global customers.

For coffee concentrates and similar oxygen-sensitive liquids requiring a 9-month ambient shelf life, the film OTR should typically be targeted below 0.05 cc/100 in²/24 hrs, necessitating the use of foil or high-end EVOH laminated barrier materials.

Multi-layer films integrate distinct layers for separate functions: a structural layer (strength), a barrier layer (low OTR), and a sealant layer (weld integrity). This synergistic design provides optimal protection and mechanical durability simultaneously.

Aseptic technology eliminates microbial contamination (bacteria/mold) during the filling process. This, combined with the high oxygen barrier, is essential for achieving a stable, non-refrigerated Extended shelf life Bag-In-Box for beverages.

The universally recognized industry standard for measuring the Oxygen Transmittance Rate (OTR) of films is ASTM D3985.

Flex-cracking, common in aluminum foil barriers subjected to bending stress, creates microscopic pinholes. These holes negate the barrier performance, leading to rapid oxygen ingress and premature failure of the **Tea & Coffee Liquid Bag-In-Box (BIB) Packaging**.