Agrochemical Bag-In-Box (BIB) Packaging - Efficient and Controlled Liquid Storage Solution

Product Features

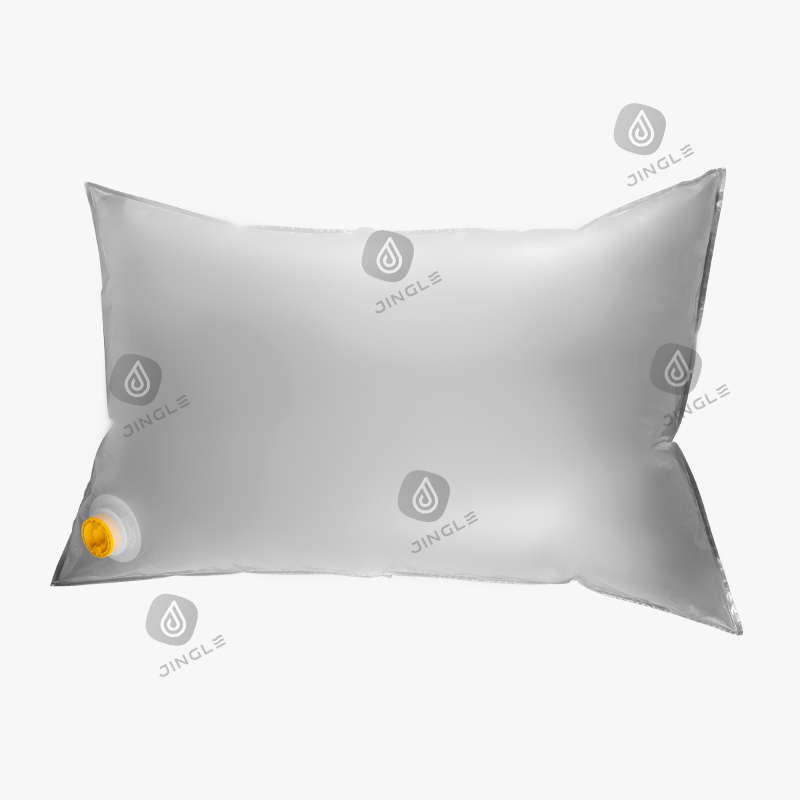

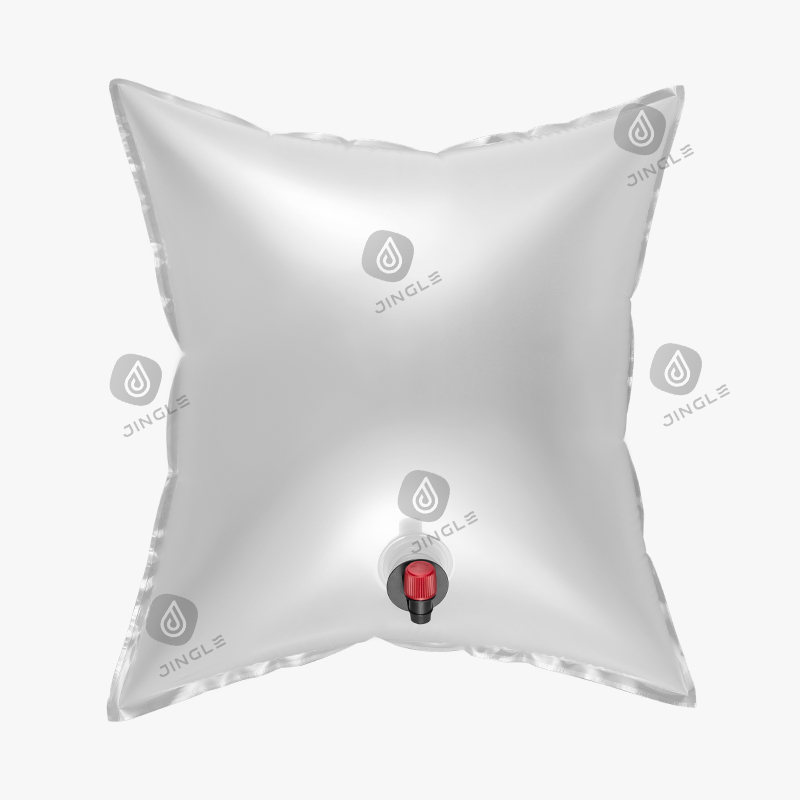

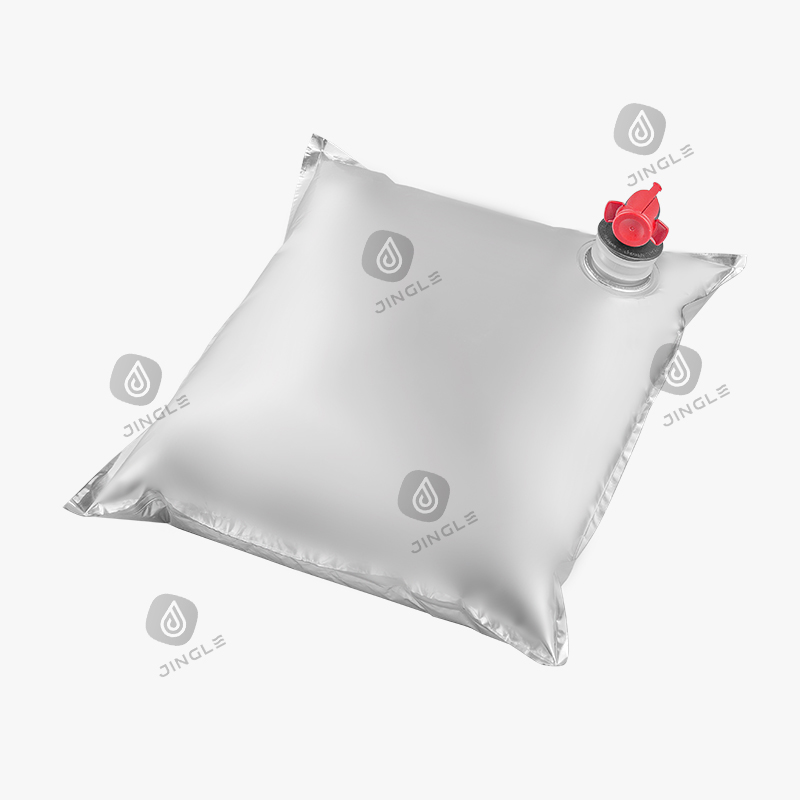

- Flexible Containment: Designed to store and transport liquid agrochemicals in controlled volumes, reducing the risk of spillage and contamination.

- Durable Material Composition: Constructed from multilayer films that provide chemical resistance, puncture protection, and barrier performance against oxygen and moisture.

- Integrated Dispensing System: Equipped with precision valves to allow accurate dosing and minimize waste during application or transfer.

Product Description

The Agrochemical Bag-In-Box (BIB) Packaging system is engineered to provide a secure, efficient method for the containment, transport, and dispensing of liquid agrochemicals. Its design incorporates multilayer polymer films that ensure chemical compatibility and structural integrity under typical handling conditions. This packaging solution is particularly relevant for formulations such as liquid fertilizers, herbicides, and insecticides, where precise volume management and contamination control are critical.

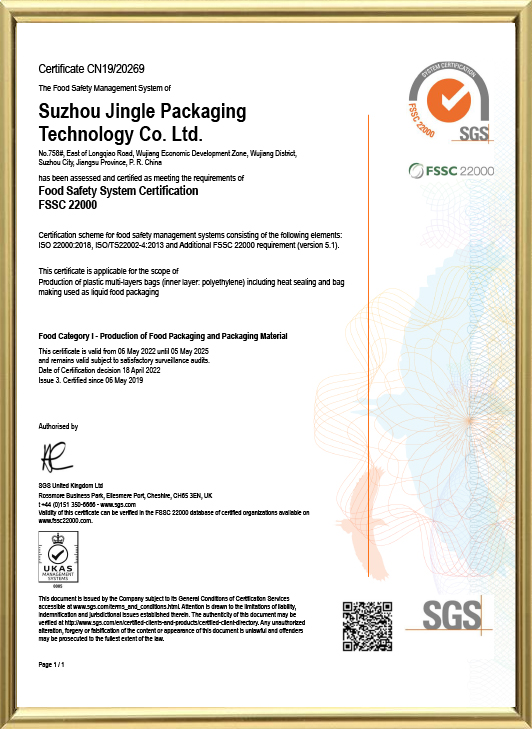

Manufactured in compliance with international standards for chemical packaging, the BIB system includes quality certifications and testing protocols that verify leak resistance, material strength, and valve performance. The system is optimized for integration into automated filling and dispensing lines, supporting operational efficiency and regulatory compliance in agricultural supply chains.

Technical Specifications

| Parameter | Value | Unit |

| Capacity Range | 5 - 1000 | Liters |

| Bag Material | Multilayer Polyethylene/PA/PE | — |

| Outer Carton | Corrugated Board | — |

| Valve Type | Precision Spout with Locking Mechanism | — |

| Operating Temperature | -20 to 60 | °C |

| Shelf Life | 24 | Months |

Application Areas

This product is suitable for the following industrial scenarios:

- Storage and transportation of liquid fertilizers, herbicides, pesticides, and biostimulants.

- Integration into agricultural supply chain systems requiring controlled dispensing.

- Packaging solutions for automated filling lines in agrochemical manufacturing facilities.

FAQ

1. What types of agrochemicals can be safely stored in Bag-In-Box packaging?

The BIB system is compatible with a wide range of liquid agrochemicals including fertilizers, herbicides, insecticides, and biostimulants. Compatibility depends on the chemical formulation and pH, and testing is recommended for highly reactive compounds.

2. How does the Bag-In-Box system help reduce contamination and waste?

The integrated valve system allows precise dispensing of liquids without exposure to air, which minimizes oxidation, contamination, and spillage. The multilayer bag material also prevents interaction with external environmental factors, maintaining the integrity of the product.

3. Can Bag-In-Box packaging be used in automated filling and dispensing lines?

Yes, the BIB design supports automated filling and dispensing systems commonly used in agrochemical production facilities. Standardized valve connections and carton dimensions facilitate smooth integration, enhancing operational efficiency.